Exploring a Thorough Series Of Mining Equipment Parts for each Requirement

Exploring a Thorough Series Of Mining Equipment Parts for each Requirement

Blog Article

Introduction Necessary Mining Equipment Components for Ideal Operations

In the intricate globe of mining operations, the smooth functioning of equipment is vital. Behind the scenes of every successful operation lies a thorough selection of important parts that play a crucial function in making certain optimum efficiency. From drill little bits that sculpt through rock with precision to conveyor systems that simplify material transport, each element is a gear in the equipment of performance. As we look into the midsts of mining tools essentials, a more detailed consider the complex information and functionalities of these components unveils an interesting globe where effectiveness and reliability are the keystones of success.

Value of Proper Drill Little Bits

Proper option and upkeep of drill little bits are basic for optimizing mining effectiveness and productivity (mining equipment parts). The type of drill little bit selected must line up with the particular geological problems of the mining website to make sure ideal efficiency.

Normal upkeep of drill little bits is equally crucial to ensure longevity and performance. Dull or broken drill little bits can cause reduced boring speed, enhanced endure exploration devices, and inevitably, decreased productivity. Upkeep jobs may consist of developing, regrinding, or replacing worn parts to maintain the drill bits in top working condition.

Trick Parts in Conveyor Solutions

Reliable product transport in mining operations heavily depends on the functionality and integrity of essential parts in conveyor systems. One important part is the conveyor belt itself, which lugs the materials along the mining website. The top quality and resilience of the conveyor belt are important to avoid breakdowns and make certain a smooth circulation of materials. Another vital component is the idler, which sustains the conveyor belt and aids maintain appropriate tension for efficient operation. Idlers are tactically positioned along the conveyor system to minimize rubbing and support the weight of the products being transported - mining equipment parts.

Important Filters for Equipment Upkeep

An indispensable facet of making sure the longevity and optimum performance of mining equipment exists in the thorough selection and maintenance of essential filters. Filters play a vital function in securing mining equipment from pollutants that can trigger wear and tear, bring about expensive fixings and downtime. Dirt, particles, and dirt are pervasive in extracting settings, making the correct filtration system crucial to equipment toughness.

Filters in mining equipment serve to catch particles that might penetrate sensitive components such as hydraulics, engines, and transmissions. On a regular basis changing these filters according to maker suggestions is crucial to prevent clogging and guarantee efficient operation. Disregarding filter upkeep can cause lowered tools life-span, minimized performance, and boosted gas usage.

Vital Wear Parts for Crushers

In the realm of mining tools upkeep, one crucial facet that requires interest is the identification and substitute of necessary wear parts for crushers. Crushers play an essential role in click here to find out more the ore processing and material decrease procedures within mining operations. A few of the essential wear components that are necessary for the efficient performance of crushers consist of the complying with:

** Crusher Liners **: These are essential in protecting the crusher covering from deterioration caused by the material being crushed.

** Jaw Layers **: Found in jaw crushers, these parts are accountable for crushing the material versus a dealt with surface area.

** Mantles and Concaves **: These parts are crucial in gyratory crushers, where they aid in crushing the product into a much more polished form.

Regular examination and substitute of these wear components are imperative to make sure the crushers run at their ideal efficiency, minimizing downtime and making best use of productivity in mining procedures. Appropriate upkeep of these wear components can substantially impact the overall performance and long life of the crushers, eventually adding to the success of mining activities.

Function of Hydraulic Cylinders in Mining

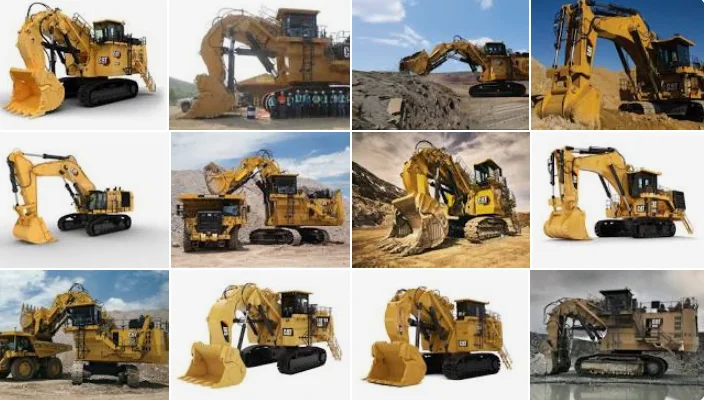

Playing sites a critical function in contemporary mining operations, hydraulic cyndrical tubes are important parts that help with the efficient functioning of numerous heavy equipment. These hydraulic cylinders are important for powering vital mining devices such as excavators, excavators, drills, and loaders.

Hydraulic cylinders in mining devices are designed to withstand harsh operating problems, including extreme temperature levels, high stress, and heavy lots. Their durability and integrity add to the general efficiency and safety of mining procedures. Appropriate maintenance and routine assessment of hydraulic cylinders are necessary to make certain optimal efficiency and prevent pricey malfunctions that can stop mining tasks. Fundamentally, hydraulic cyndrical tubes play a vital role in boosting the performance and efficiency of mining operations worldwide.

Verdict

To conclude, it is important for extracting operations to utilize correct drill bits, essential components in conveyor systems, important filters for tools maintenance, necessary wear components for crushers, and hydraulic cyndrical tubes. These crucial mining devices parts play a significant duty in making sure optimal procedures and making the most of effectiveness in the mining industry. By buying dependable and top quality tools parts, mining firms can improve performance and minimize downtime, inevitably resulting in a much more effective operation.

In the complex world of mining procedures, the smooth functioning of devices is extremely important. By spending in superior filtration systems and adhering to a rigorous maintenance schedule, mining procedures can improve equipment dependability, minimize downtime, and eventually enhance performance.

In the realm of mining tools upkeep, one crucial aspect that requires focus is the recognition and substitute of important wear parts for crushers. These necessary mining devices components play a substantial role in making best use of and ensuring optimal procedures efficiency visit this page in the mining sector. By investing in trustworthy and premium tools components, mining companies can boost efficiency and decrease downtime, eventually leading to an extra successful operation.

Report this page